PRODUCT

Dongguan Mingyu precision mould Co., Ltd

Contacts:Mr. Jiang

Phone:13790680950

Tel:0769-89068561

address:No.4, Xinchun Road, Zhenxing District, Shangsha village, Chang'an Town, Dongguan City, Guangdong Province

Dongguan Mingyu precision mould Co., Ltd

Contacts:Mr. Jiang

Phone:13790680950

Tel:0769-89068561

address:No.4, Xinchun Road, Zhenxing District, Shangsha village, Chang'an Town, Dongguan City, Guangdong Province

Professional focus, service to the heart, perfection

Strong and guaranteed

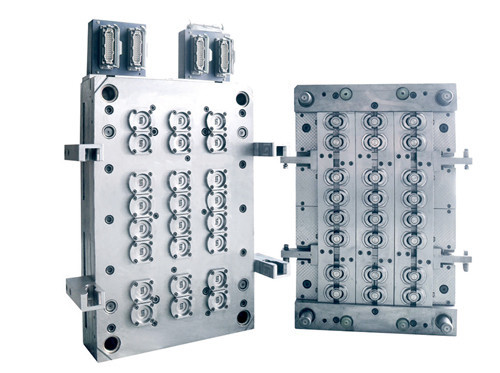

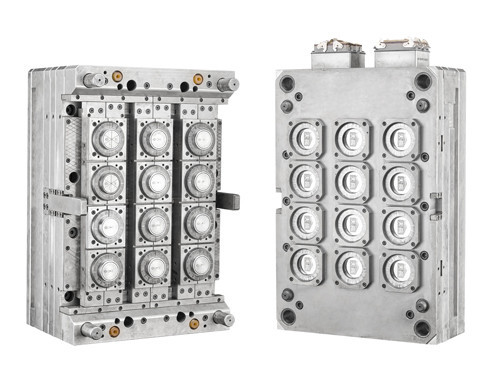

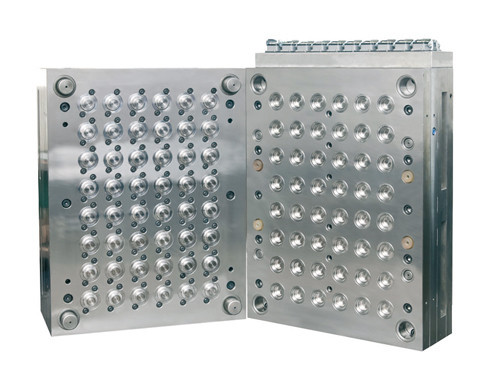

Professional design, manufacturing and production of hot runner mold enterprises, R & D and design of thin-walled mold including die labeling technology

Design and develop precision multi cavity plastic mold including die inner closure technology, with rich manufacturing experience

Mingyu bottle cap mold has a durable mold maintenance program, as well as a number of technical innovations, which greatly reduces the cost of mold renovation and production downtime

Fully implement the requirements of the quality management system, production strictly control the quality;The after-sales service network system covering the whole country enables you to find us at any time!

The manufacturer provides direct sales, avoids the superposition of intermediate interests, optimizes raw material suppliers, outsourcing manufacturers and purchasing processes, reduces raw material costs, optimizes product structure and production processes, ensures quality and saves production costs

The company has a professional after-sales service team to help you solve the pre-sale, after-sale and other problems at any time, so that your production is more smooth and production efficiency is greatly improved;

Implement comprehensive quality management and enterprise standards, and carry out testing management in strict accordance with the standards.

The leading team is a young but experienced team, with young people's unique vigor, drive and innovation awareness; with a number of high-quality professional research and design personnel and perfect after-sales service system.

With the wide application of plastic products, such as cosmetic bottle caps and beverage packaging containers, the surface of plastic mold cavity is often required to achieve the degree of mirror polishing. Polishing can not only increase the beauty of the workpiece, but also improve the corrosion resistance and wear resistance o…

[View details]

The maintenance of plastic bottle cap mold is an effective measure to ensure the normal operation of injection mold. The maintenance of equipment mainly includes cleaning and wiping, inspection and adjustment, lubricating and oiling, etc., mainly including the following points.1. Quality of certified productsTo ensure that the pl…

[View details]

The essence of the grinding process of plastic bottle cap mold is that the workpiece is grinded on the metal surface, which deforms under the instant extrusion and friction of numerous abrasive particles, and then turns into abrasive particles, forming a smooth surface. The whole process of grinding is represented by the effect o…

[View details]

As the intangible assets of an enterprise, it can greatly enhance the image of the enterprise in the industry, deeply rooted the good image of the enterprise and its products in the minds of consumers, and more smoothly obtain high add…

[View details]1. How long can we get a reply after we send you an inquiry?We will reply to you within 12 hours after receiving the inquiry on weekdays.2. Are you a direct manufacturer or a trading company?We are a mold factory with more than 20 …[View details]

You can provide samples, drawings or requirements, we can make the mold you need And we have rich experience in heteromorphic bottle embryo.[View details]

The company has a complete set of machine tools and equipment for mold processing. All processing processes are controlled by the company and the latest and most advanced processing technology is used.[View details]

The company has nearly 100 employees and more than 20 professional technicians and engineers.[View details]

First, ensure the quality of raw materials Second, after each processing procedure, we will check each part Third, after the final inspection of the samples, we will send them to the customer for confirmation Fourth, we will carry …[View details]

Before signing the contract, we will confirm the payment terms with you. Generally speaking, our quotation is FOB, 30% advance payment is required. After the customer confirms that the bottle embryo sample is qualified, the balance…[View details]

Copyright © Dongguan Mingyu precision mould Co., Ltd Record number:粵ICP備19142250號(hào)